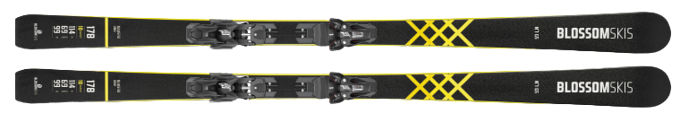

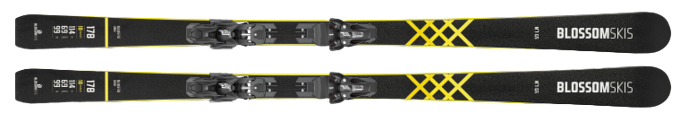

- A set with plate WCR14 and bindings Tyrolia ST 14.

Zahrnuté

BLOSSOM SKIS N°1 GS

Giant Slalom skis designed with a more accentuated side cut in respect to the FIS models. NUMERO UNO GS skis are built using more moderate materials in respect to the Squadra Corse FIS category, from which they inherited their performance, making this ski suitable for the majority of expert skiers. If you are looking for a high speed ski on medium and wide turn radius, the NUMERO UNO GS model is the right choice, with its safe, energetic edge grip, even on hard packed snow and ice.

Geometry

| Lenght | Sidecut | Radius |

|---|---|---|

| 166 | 114 – 69 – 99 | >17 |

| 173 | 114 – 69 – 99 | >17,5 |

| 178 | 114 – 69 – 99 | >18 |

| 183 | 114 – 69 – 99 | >20 |

Profile

| Racing | Piste | Powder |

| 7/10 | 10/10 | 1/10 |

Technologies:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Technologies in Blossom Skis

We have been making skis for over 20 years according to the highest production standards and using the finest materials on the market.

Sandwich Tech

All Blossom skis are constructed using sandwich technology, a production method based on overlapping materials, with lower and upper layers surrounding the wooden core. This type of construction controls longitudinal elasticity and bending rigidity.

Anti Scratch

The covering material gives the ski its aesthetic appearance and resistance to scratches. Each collection is renewed with different innovative materials, while always maintaining a good balance between beauty and resistance.

Titanal

This is a steel and aluminum alloy dedicated to the world of skis, together with the wood and Fiberglas core, it is one of the main ingredients that determine the performance of one ski compared to another, depending on different thicknesses: 0.4 – 0.6 – 0.8 or 1, used to create the character of the ski.

Fiber Glass

An indispensable component in a ski sandwich, used with different thicknesses according to the specific ski.

Wood Core

We dedicate special attention to the development and distinctive character of a ski, and we have studied various blends of wood to give each ski different levels of reactivity, elasticity, and weight. We use the following types of wood: Poplar, Beechwood, Ash wood, and Paulownia.

Running Base

The base of Blossom skis is sintered with high molecular weight, giving the ski optimum glide.

![]()

World Cup Edge

The edges of our entire collection are in a steel alloy that guarantees excellent hardness, from 48 HRC to 52 HRC, capable of ensuring maximum grip in any snow conditions.

Phenol

This material is used for racing sidewalls, making the ski more aggressive and offering high reaction intensity, while protecting the inside of the ski.

![]()

Radical Sidewall

The sidewalls of our skis are slightly concave, providing the ski with better inclination at the start of a curve, more stability, and better adhesion of the materials inside of the ski.

About Blossom Ski brand

20 YEARS OF SKIING

Our home had to be Valchiavenna because the very first ski factory in Italy, Persenico, was founded in Chiavenna in 1906. Their skis contributed to the explosion of the Valanga Azzurra, the Italian national alpine ski team.

From this early beginning, the production of skis developed consistently for years, and then gradually tapered off when finally, in 1999, production of skis was restarted in this historic location. This history is the inspiration behind the name Blossom.

Our beginning started with two ski enthusiasts that decided to revive this historic tradition. These two friends were Franco Moro, an entrepreneur from Valchiavenna, and the speed coach for the national ski team, Mario Cotelli, the technical director of Valanga Azzurra.

This combination of technical expertise and entrepreneurial spirit led to the founding of Blossom Skis and an immediate decision to orient the company to build highly technical, top of the line skis for superior performance using the best quality materials, paying attention to the finest details, similar to tailor-made production in a custom studio. In 2012 the corporate structure underwent changes, and since then company has been run exclusively by the Moro family. Mario Moro, a competitive skier for over two decades, became the Product Development Manager, following the design process up the final testing stage. Since then the team has grown with him, adding a range of skills and expertise, because at Blossom this intersection between people, the blending of ideas, creativity, know-how, and points of view are what make the difference. This is what makes Blossom skis stand out from the rest.

Blossom Skis is a company that, in the age of standardized production, chooses to offer hand-made, tailor-made products: we control every stage of the process, the quality of all materials, and ensure 100% Made in Italy production. Deeply rooted in our Valchiavenna tradition, the Blossom team works tirelessly to combine the best designs, the highest performing materials, and most effective production technologies towards a single objective: to give each customer “his or her” own pair of skis, designed for that person’s technical skill, type of snow and preferred terrain. How can we be so sure about the performance of our skis? We design our skis with passion, we build them with attentive care, and then we test them. All of them.